Wanhao Boxman-1

425 € 469 €

Did you make your first 3D print with your SLA, DLP or LCD panel 3D printer?

Brilliant! After you have cleaned them, you have to harden your parts to get durable components.

The best way to do this is to use the Wanhao’s Boxman-1 UV LED post-curing chamber.

The most important product features:

– UV post curing chamber

– SLA, DLP and daylight 3D prints

– Large interior space of 32*20*20 cm

Varastossa:

Esittely

Wanhao Boxman-1 UV Curing Chamber / Box – Cure your SLA, DLP & daylight 3D prints

Automatically cure your SLA, DLP, or LCD 3D prints with Wanhao’s Boxman-1 UV post-curing chamber. To obtain the final material properties with resin-based 3D printing, you must cure your 3D prints. Following the additive manufacturing process and washing off, the hardening process after the additive manufacturing process stimulates the free particles (radicals) to polymerize almost completely. Only then will you receive the final material properties of your resin.

Product properties:

UV post-curing chamber for DLP, SLA and Daylight 3D prints

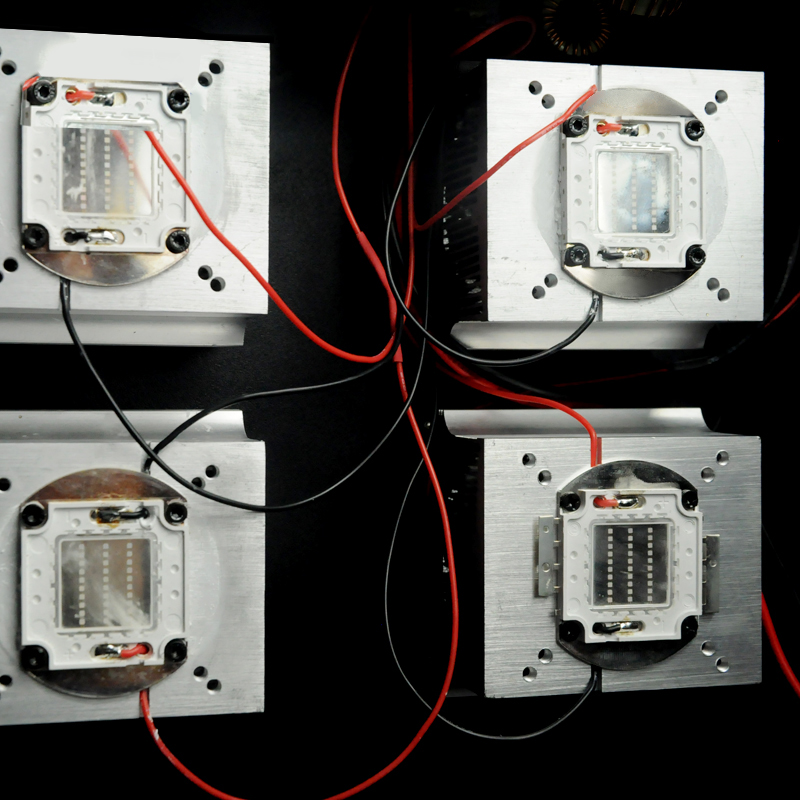

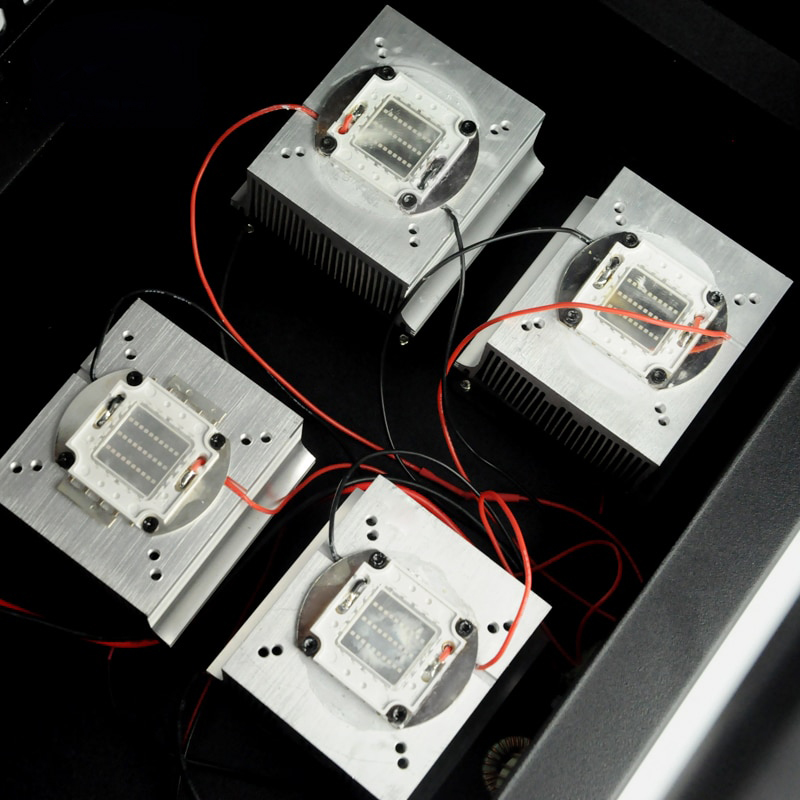

4 UV LED sources cure from each side

Large interior of: 32*20*20 (L*W*H in cm)

Give your components their final material properties

Works with resin for DLP, SLA and daylight 3D printers

Optimized for Wanhao UV resin

Automatically harden your SLA, DLP and LCD 3D prints with Wanhao Boxman-1

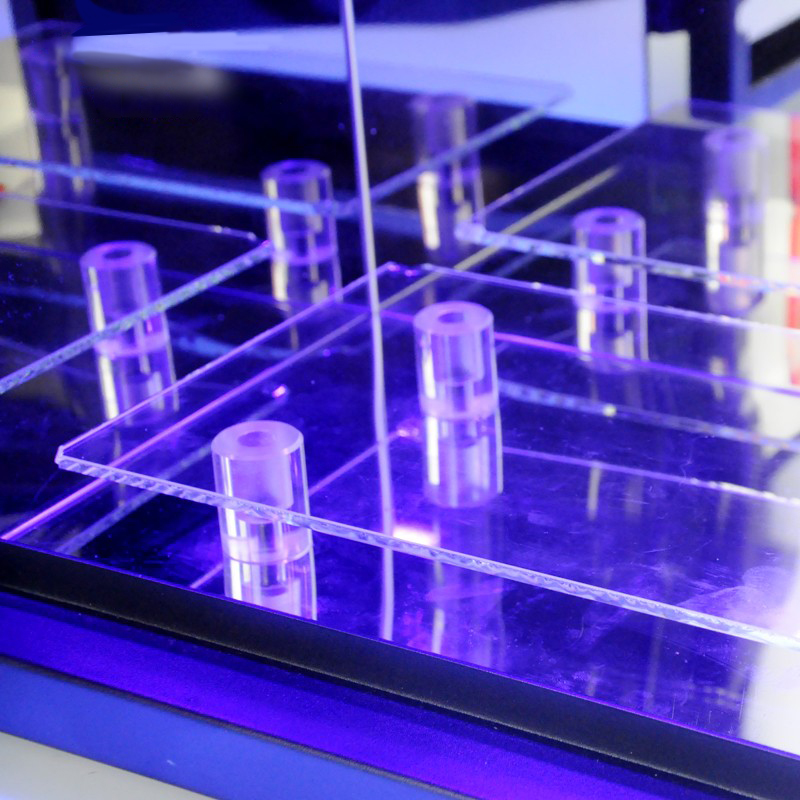

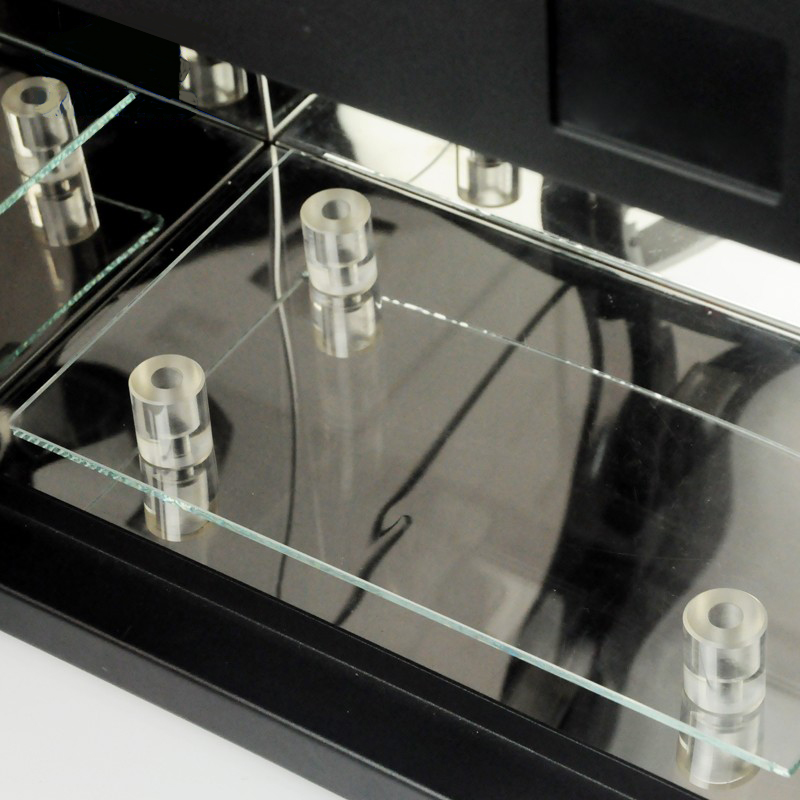

The new Wanhao Boxman-1 UV post-curing chamber is equipped with 4 UV LED light sources and mirrors. These are placed inside the box in such a way that your component(s) are perfectly illuminated from all sides. This ensures that your object cures evenly from all sides. By adding UV light, the free radicals in the resin polymerize almost completely and your part automatically receives the final material properties.

Reworking resin with the following material properties:

Hard

Firm

Durable

Flexible

Castable

Dental

Biocompatible

Hardness of several components at once after

The very spacious interior (32*20*20 cm) allows you to easily process several 3D prints at once. In addition, the box offers enough space to place an articulator (for dental and dental technology) inside. If necessary, the UV light source can be easily changed. The new Wanhao B1 UV-Curing Chamber is optimized for use with Wanhao UV-Resin. However, you can also cure resin from other manufacturers.

What do I have to do after 3D printing with resin and before curing?

First the material should be cleaned in an alcohol bath (Isopropanol / IPA). This will remove any resin left on the surface after 3D printing. Make sure that you get a good and clean surface. It is best to place your component in a bath of isopropanol alcohol for about 10 minutes. This will remove any excess material from the surface.

Why buy the Wanhao Boxman-1 UV post-curing chamber?

The UV light source emits stable, concentrated and coherent UV light waves for fast processing of 3D printed products with photopolymer resins. The post-curing process increases the hardness and longevity of your 3D prints.

Buy the Wanhao Boxman-1 UV Post Cure Chamber to post-process and automatically cure your SLA, DLP or LCD 3D prints.

Tekniset tiedot

Brand Name WANHAO UV led curing box

Light source 4 UV LED array module

Power(W) 120W

Voltage 110V/ 220V switchable

Net Weight 14.5KG

Wavelength 405nm

Dimension (L*W*H) 43*30*35cm

Curing Area(L*W*H) 32*20*20cm

Touch LCD screen(L*W) 57.6*43.2mm

Fan size (L*W*H) 85*85*10mm

Certification CE,FCC

Usage Curing print model

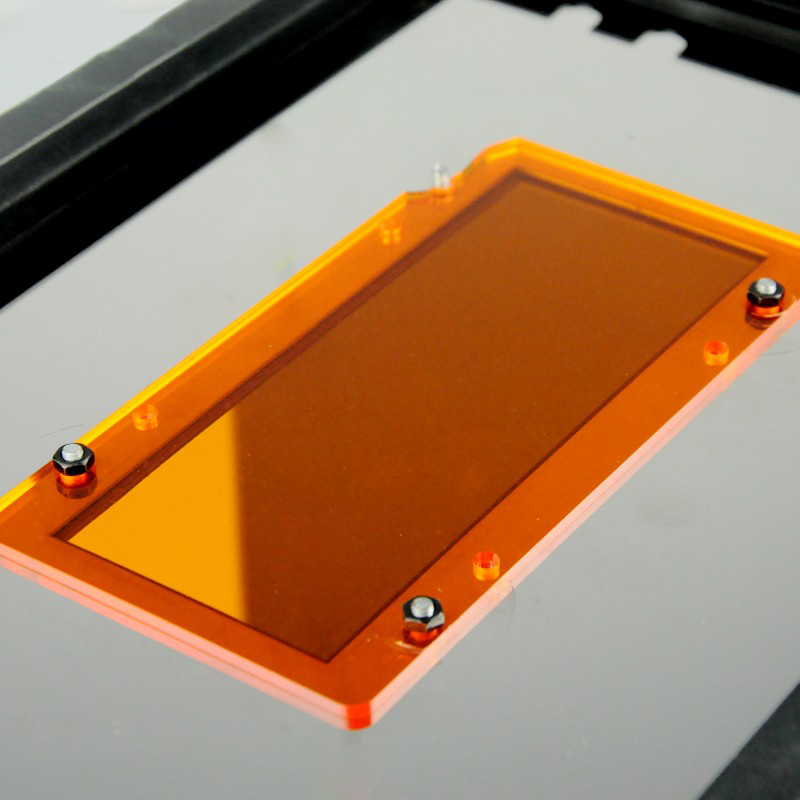

Perspective screen (L*W) 15*6cm

UV Led warranty 2000hours decay 30%; 5000hours decay 50%;

Typical application Hobbyist , dental, jewelry

Wanhao Boxman-1

425 € 469 € Lisää ostoskoriin